Why Your Business Needs Spray Foam Insulation

Spray Foam Is Easy to Install

The last thing you want to do is face a major renovation project while you are still open for business. Rolled insulation and foam core products both require extensive work to put them in place because you must physically secure them behind the wall. This could prove disruptive to your workplace and your customers.

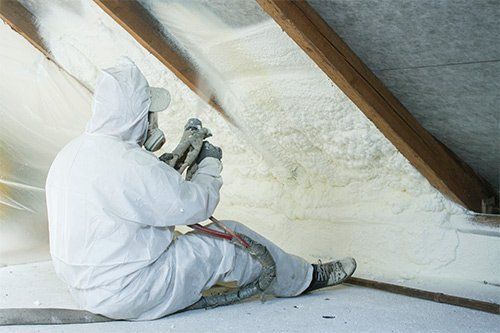

Spray foam, on the other hand, installs easily and quickly. The spray nozzle makes it easy to fill harderto-access spaces, and the foam expands up to 100 times the initial volume, which fills gaps quickly and securely. That means minimal disruption of your work environment and a quick installation solution.

Spray Foam Minimizes Moisture Problems

Rolled fiberglass insulation is a magnet for moisture problems. Rolled insulation leaves all sorts of air gaps in the walls, and those air gaps allow for condensation and moisture accumulation. Over time, that moisture buildup soaks into the insulation because the porous nature encourages absorption.

Moisture buildup like this can lead to all sorts of problems in your building. Mold and mildew in the walls due to the moisture will eventually lead to poor air quality in your building. Employees and customers could end up sick, which is dangerous for your company's liability.

Spray foam insulation helps to minimize this risk. Since the foam expands so significantly, the foam will fill all of the air gaps and spaces where condensation could form otherwise. That solid space keeps moisture and condensation away because it has no space.

Not only does preventing moisture eliminate the risk of mold and mildew, but the lack of moisture also eliminates the potential for corrosion of metal structural components due to moisture and deterioration of wood beams.

Spray Foam Insulation Mitigates Noise Transfer

Especially for commercial buildings in industrial areas, noise seems to be a fact of daily operation. With the right insulation, you do not need to hear that noise. Even noise transfer within your building, such as from your manufacturing floor to your customer service area, can be controlled.

Insulation such as rolled fiberglass batting will not provide you with a sufficient noise barrier because of how porous and fibrous that fiberglass is. Without a solid structure, insulation cannot effectively block noise transfer.

Spray foam insulation, on the other hand, forms a solid barrier inside the walls. When the walls have adequate insulation with spray foam and the material has cured, that insulation provides you with a sound buffer that can keep your work environment more peaceful and effective. The sound barrier can also reduce the risk of noise complaints in a mixed-zoning environment.

Spray Foam Helps With Pest Control

Pest infestations in a commercial building can be a serious liability and safety issue. Many forms of insulation have soft fibers and paper content that serve as food sources and nesting material for many pests, which increases the chances of pest problems.

Spray foam insulation not only eliminates the nesting and food source of other insulation products, but also creates solid space in the walls. The solid space means less room for pests to gain access to your building.

As you can see, spray foam is an ideal insulation choice for commercial properties. Contact us at Guy M. Beaty Co., Inc., today for more information.