Insulation Options for Your Commercial Building

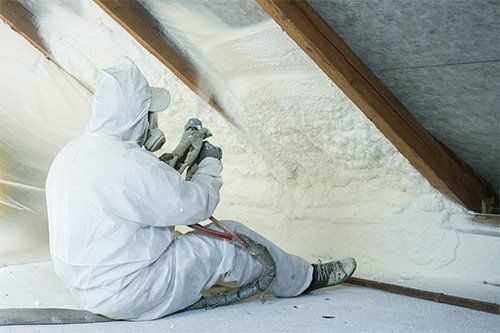

Spray Foam Insulation

Spray foam begins as a liquid foam. It is then sprayed into the area requiring insulation, where it expands to fill the space before it cures. The foam itself is made from polyurethane, a compound that minimizes heat transfer and provides superior insulative properties. Spray foam can also be used to seal cracks in walls or other surfaces.

Uses

The main benefit of spray foam is that it can be installed in existing buildings. Generally, only a small hole needs to be drilled into a wall in order to spray the insulation into the cavity, so the process isn't invasive at all.

There are three types of spray foam insulation. High-density foam, which provides the highest insulation level for spray foam, is typically used to insulate surfaces exposed to exterior elements, such as the roof and exterior walls. Medium- and low-density varieties are used in attic and interior wall cavities that don't vent to the outside.

Batt Insulation

Batt insulation is commonly used in residential buildings, but it is also an option in a commercial structure. It is made of fiberglass and in comes in sheets or rolls, which are installed in the walls, attic, and crawlspaces of a building.

Uses

Batt insulation is typically installed in new construction, simply because the walls or ceiling must be opened up in order to install it. It can also be installed at the time of building renovations or if the building has an easily accessible area for installation, such as the attic.

This insulation comes a large range of R-values, which indicate the level of insulation provided.

Radiant Barriers

Radiant barriers are little more than reflective sheets. These sheets are designed to reflect heat away from where ever they are placed within the building. The sheets themselves are typically very thin and foil-like, although some radiant barriers are installed over foam boards in order to provide additional insulation.

Uses

Radiant barriers are almost exclusively used in roof and ceiling applications because they don't reduce thermal conduction, which is the transfer of heat or cold between spaces. Instead, the barriers simply reflect heat away. In the summer, this can help keep the upper floors of your commercial building cooler.

This type of insulation is primarily used in hot climates or on buildings with high sun exposure, simply because it only helps cool a building and it does not provide any heat gain. Properly installed radiant barriers can reduce your building cooling costs by up to 10 percent.

Blown-In Insulation

Blown-in insulation is also called loose fill. It is made of loose, fluffy pieces. These pieces are loaded into a motorized blower, which blows the insulation into wall, ceiling, or floor cavities.

Uses

This type of insulation is a great choice for increasing the insulation in existing buildings. Walls do not need to be removed for installation. Instead, a hole is drilled near the top of the wall and then the insulation is blown in to fill the cavity. Blown-in insulation works especially well for irregularly shaped cavities.

Blown-in insulation is typically made from fiberglass, rock wool, or cellulose. Fiberglass is the most cost effective option, so it is commonly used. Rock wool is also popular, simply because it both provides insulation and is fire-resistant. For buildings trying to meet green building certification, cellulose is sometimes favored because it is made from recycled newspaper.

Contact Guy M. Beaty Co., Inc., for more information on your insulation options.